dozhpad Company started its activity in 2017 with the aim of entering the light construction materials industry by establishing a fully automatic sandwich panel production unit based on modern European technology, under the trade name dozhpad Panel, and relying on more than seventy years of successful presence of dozhpad name in the Iranian industry. The production lines are of continuous production type, which has a daily production capacity of more than three thousand meters of polyurethane sandwich panels. dozhpad sandwich panel products are produced and marketed in two functional formats, ceiling and wall, in different thicknesses and according to the needs of customers.

The late Haj Mohammad Hossein Jaber Ansari founded the shelving industry in Iran in 1953. Over the past seven decades, dozhpad Group has succeeded in keeping pace with Iran’s industrial development and offering its services and products at the national and regional project levels; to the extent that millions of square meters of warehouses in industrial, service, administrative, oil, gas, petrochemical, automotive, household appliances, food, pharmaceutical, health, etc. sectors in Iran and 30 countries around the world have been equipped with various dozhpad storage systems. In this regard, obtaining prestigious global certificates has completed dozhpad’s honors and has been a seal of approval for its credibility.

dozhpad Company (private joint stock company) with more than seventy years of positive and brilliant history, as the largest manufacturer of material and goods storage systems (types of shelving) in Iran and the Middle East, is responsible for consulting, designing, manufacturing, supplying, installing and providing complete solutions in a wide range from a simple mesh shelving system to the largest and most complex fully automated warehouses. With experienced specialists and benefiting from world-class knowledge, dozhpad Company has the ability to provide solutions that not only solve today’s problems, but also ensure the fulfillment of the organization’s future needs.

Call Center

02174435777

Administrative

02174435000

info@dozhpad.com

hours

09:00 to 21:00

Direct communication

In this system, in addition to the role of storing stored loads, the shelves also act as a supporting structure for the walls and ceiling, thus eliminating the need for a warehouse building structure; in other words, this system itself constitutes the main and major part of the warehouse building, which is done by strengthening the shelving structure. The design of such warehouses is done according to the climatic and seismic characteristics of the desired area. In most self-storage warehouses, fully automatic machines are used in various operations; such as placing and retrieving loads and transporting and moving loads at ground level and at height. In this system, operators monitor the goods and machines from the control room with the help of computers. It is worth noting that it is possible to operate semi-automatic and even manual systems in self-storage warehouses.

Colored sheet warehouse

Fully automatic packaging machine

Fully automatic layout machine

How to load sandwich panels

Example of a picture of building your own shed warehouse

dozhpad Company, with valuable experience and a long history, is the only Iranian company capable of providing consulting, design, production, and implementation services for self-contained warehouses on a turnkey basis (EPC).

In the continuous method, polyurethane sandwich panel production (polyurethane injection) is multi-component. A high-pressure injection machine is used to inject the main components of isocyanate (polyol) and catalysts at different temperature ratios. The injection ratio of isocyanate (polyol) and catalysts depends on the thickness of the sandwich panel and its production speed. Usually, sandwich panels with lower thickness are produced at higher speed and thicker sandwich panels at lower speed.

General plan of polyurethane sandwich panel production (Continuous)

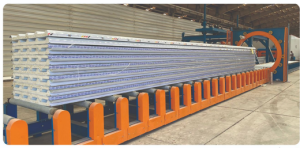

Sandwich panel continuous production (line)

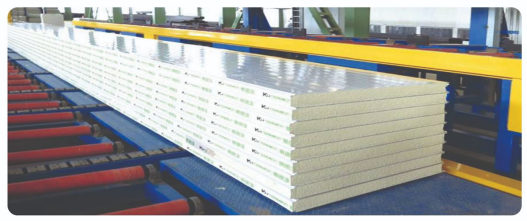

Currently, large factories use continuous and automatic lines to produce sandwich panels. dozhpad sandwich panels are produced by a continuous automatic machine. The length from the beginning to the end of the continuous line is about 120 meters, and the production process in it is generally as follows:

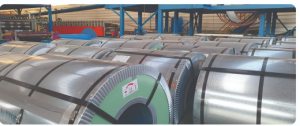

The top and bottom sheets of the sandwich panel are placed in this machine as coils and are opened and directed towards the rollformer by a coil opener.

The task of this machine is to convert flat sheet into formed sheet (ceiling or wall).

In this part, before the top and bottom sheets are joined together, polyurethane foam is poured onto the bottom sheet and then it enters the press machine. (The injected foam is based on a predefined formula, according to the desired density and thickness of the sandwich panel).

The cutting operation is carried out according to the desired length and number, and the cutting machine automatically cuts the required sandwich panels.

The auto stacker stacks the cut sandwich panels on top of each other based on the number and type of panels (roof and wall) and prepares them for packaging.

Decoiler

Cutting machine

Rollform

Auto stacker machine

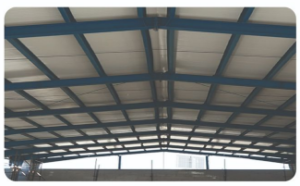

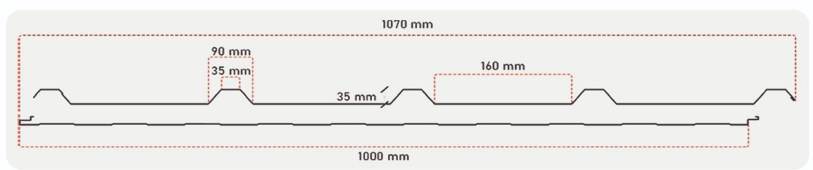

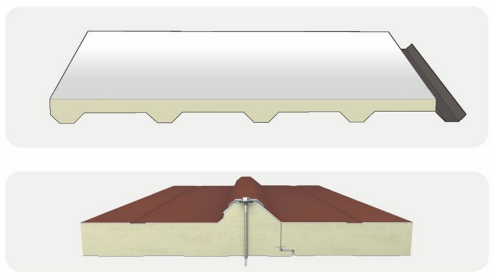

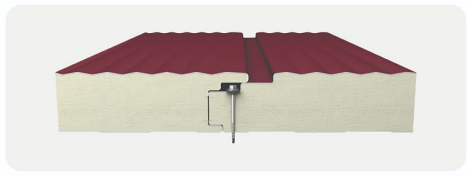

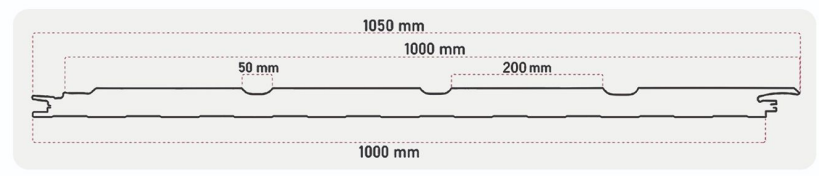

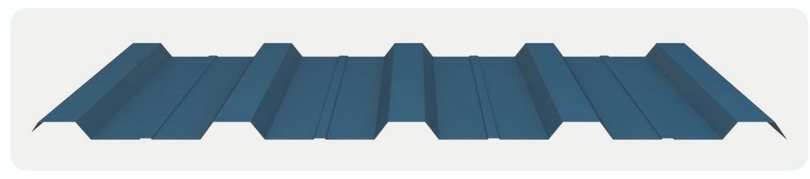

Double-layer ceiling sandwich panels are produced with a thickness of 40 to 80 mm, with rigid polyurethane injection foam (density 2+-40 kg/m3). This type of sandwich panel is resistant to plant and fungal growth and has a low thermal conductivity. The initial width of the ceiling panel is 1070 mm and its useful width and final ceiling covering is 1000 mm. The outer layers of the ceiling sandwich panels can be made of aluminum, color galvanized and aluzinc.

| Specification table for 5-step double-layer sandwich panel ceiling with polyurethane foam | ||||

| Sandwich panel thickness | 40 mm | 50 mm | 60 mm | 80 mm |

| Thermal conductivity (w/m) | 45 hundredths | 34 hundredths | 28 hundredths | 23 hundredths |

| Fire resistance class | B2 | |||

| Sound reduction | At least 16DB | |||

| Panel width (useful width) | 1000 mm | |||

| Sandwich panel length | Minimum 2 meters, maximum 14 meters | |||

The exterior of this type of sandwich panel is covered with colored galvanized sheet and its interior is covered with four-layer aluminum foil, and it is very popular due to the significant price difference with double-sheet ceiling sandwich panels. The applications of this type of panel are places where the interior appearance is not very important or where the ceiling will be covered with a false ceiling.

| Specification table for 5-step ceiling sandwich panel, one-sided sheet, one-sided foil with polyurethane foam | ||||

| Sandwich panel thickness | 25 mm | 40 mm | 50 mm | 60 mm |

| Thermal conductivity (w/m) | 90 hundredths | 45 hundredths | 34 hundredths | 28 hundredths |

| Fire resistance class | B2 | |||

| Sound reduction | Minimum 10DB | |||

| Panel width (useful width) | 1000 mm | |||

| Sandwich panel length | Minimum 2 meters, maximum 14 meters | |||

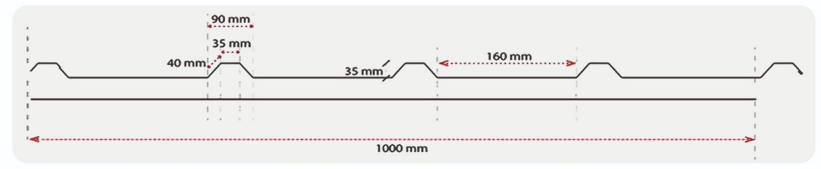

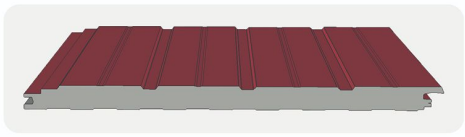

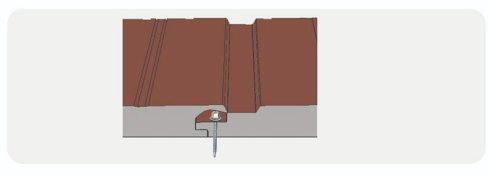

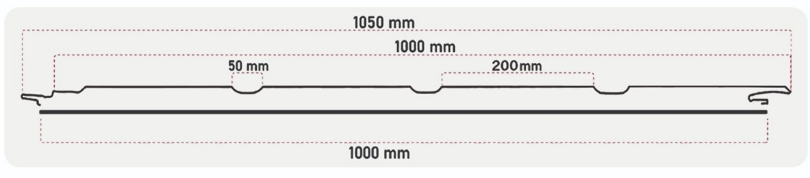

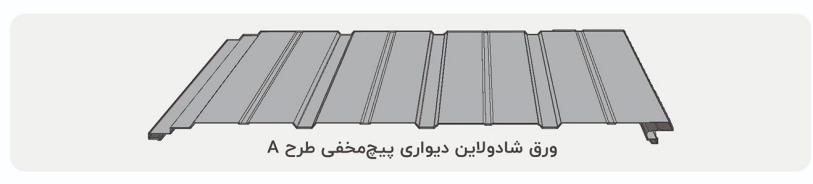

The thickness of the dozhpad concealed screw wall panel, from 50 to 80 mm thick, is 1050 mm, and its useful width is 1000 mm.

| Specification table for 3-step double-sided hidden screw wall sandwich panel with polyurethane foam | |||

| Sandwich panel thickness | 50 mm | 60 mm | 80 mm |

| Thermal conductivity (w/m) | 34 hundredths | 28 hundredths | 21 hundredths |

| Fire resistance class | B2 | ||

| Sound reduction | At least 16DB | ||

| Panel width (useful width) | 1000 mm | ||

| Sandwich panel length | Minimum 2 meters, maximum 14 meters | ||

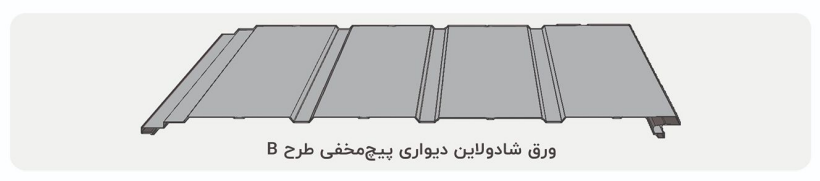

The exterior of this type of sandwich panel is covered with colored galvanized sheet and its interior is covered with four-layer aluminum foil, and it is very popular due to the significant price difference with the double-sided hidden screw sandwich wall panel. The place of use of this type of panel is spaces where the interior must be covered with another covering in architecture.

| Specification table for 3-step hidden screw sandwich wall panel, one side sheet, one side foil with polyurethane foam | |

| Sandwich panel thickness | 50 mm |

| Thermal conductivity (w/m) | 34 hundredths |

| Fire resistance class | B2 |

| Sound reduction | Minimum 10DB |

| Panel width (useful width) | 1000 mm |

| Sandwich panel length | Minimum 2 meters, maximum 14 meters |

The variety of colors in the facade sheet can be ordered based on the codes below; but it is strongly recommended that you pay special and careful attention to the effect of sunlight (UV) and the subsequent change in the appearance of the sandwich panels. It is noteworthy that white and gray colors will have the least color changes over the years, and red and blue colors will undergo more changes. Also, keep in mind that since dark colors have more energy absorption from sunlight, they will also absorb more heat.

To produce trapezoidal sheets in complex shapes, several processes are usually performed on them. These processes include operations such as deep drawing, bending, and stretching. Today, a wide range of industries use hot-dip galvanized sheets because their resistance to corrosion is very high. Since these products are subjected to tensile and bending processes, the tensile strength of their outer coating is also very important. Uniaxial tensile testing can be used to test the mechanical properties of colored trapezoidal galvanized sheets. This test is very simple and estimates the degree of ductility of the product directly or indirectly. Other results obtained from this test are:

This test is approved in ASTM and DIN standards and can be used to obtain the above parameters. Shadowline sheet is a steel sheet that incorporates several features. Some of these features are:

The first feature of Shadowline sheet is that it is zinc-plated. Zinc-plated steel sheets are also called galvanized. Steel sheets are galvanized because they are very vulnerable and weak to corrosion; therefore, zinc metal can minimize this damage.

A batch of galvanized sheets is painted after leaving the production line, under special processes. Painting gives two general properties to galvanized sheets; first, it makes their appearance beautiful and eye-catching; second, it makes the galvanized sheet more resistant to corrosion than before.

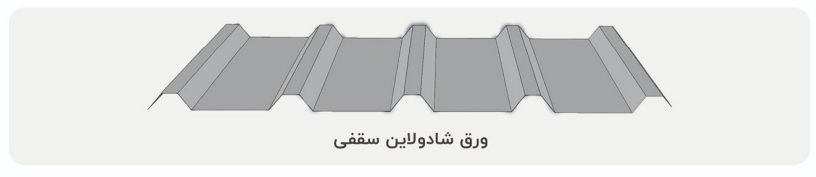

| Technical specifications table for 5-step Shadowline ceiling sheet | |||

| Load support values according to span distance | |||

| 2000 (MM) | 1500 (MM) | 1000 (MM) | BGS (MM) |

| 55 | |||

The diverse design and architecture in spaces covered with sandwich panels has made the need for additional parts inevitable. To avoid ordering errors and the needs of installers in this industry, high-consumption additional parts are used with specified technical codes; in other words, the possibility of ordering additional parts using the technical part code has been provided. Additional parts, facade construction in lengths of 2 and 3 meters, are produced and can be offered as follows.

Need help?

02174435000