To produce trapezoidal sheets in complex shapes, several processes are usually performed on them. These processes include operations such as deep drawing, bending, and stretching. Today, a wide range of industries use hot-dip galvanized sheets because their resistance to corrosion is very high. Since these products are subjected to tensile and bending processes, the tensile strength of their outer coating is also very important. Uniaxial tensile testing can be used to test the mechanical properties of colored trapezoidal galvanized sheets. This test is very simple and estimates the degree of ductility of the product directly or indirectly. Other results obtained from this test are:

- Sensitivity coefficient; Uniform elongation;

- Yield strength;

- Oscillating strain ratio;

- Total elongation;

- Tensile strength.

This test is approved in ASTM and DIN standards and can be used to obtain the above parameters.

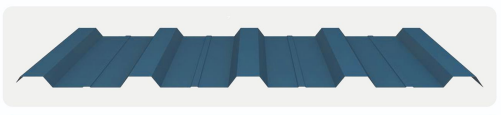

Shadowline sheet is a steel sheet that incorporates several features. Some of these features are:

Being zinc-plated

The first feature of Shadowline sheet is that it is zinc-plated. Zinc-plated steel sheets are also called galvanized. Steel sheets are galvanized because they are very vulnerable and weak to corrosion; therefore, zinc metal can minimize this damage.

Being colored

A batch of galvanized sheets is painted after leaving the production line, under special processes. Painting gives two general properties to galvanized sheets; first, it makes their appearance beautiful and eye-catching; second, it makes the galvanized sheet more resistant to corrosion than before.

| Technical specifications table for 5-step Shadowline ceiling sheet | |||

| Load support values according to span distance | |||

| 2000 (MM) | 1500 (MM) | 1000 (MM) | BGS (MM) |

| 55 | 78 | 141 | 0/40 |

| 88 | 130 | 196 | 0/50 |

| 110 | 137 | 260 | 0/60 |

| 124 | 243 | 378 | 0/70 |